Plastic and Metal

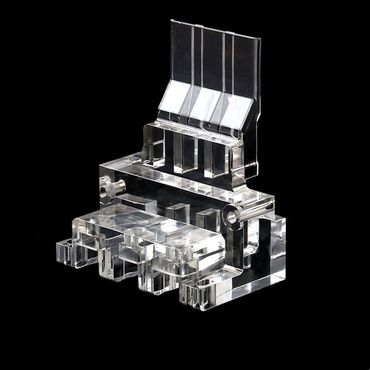

Plastic (mainly PMMA) molding & CNC

Plastic (mainly PMMA) molding & CNC

Plastic (mainly PMMA) molding & CNC

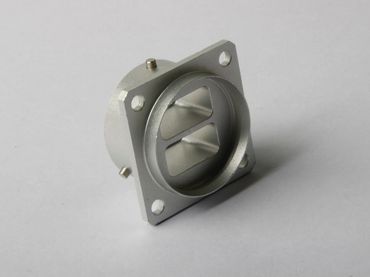

Metal CNC

Plastic (mainly PMMA) molding & CNC

Plastic (mainly PMMA) molding & CNC

PMMA Molding / Laser / CNC

Acrylic / PMMA Mold Laser and CNC Machining

Why Acrylic/PMMA

Extruded or Casted

Extruded or Casted

PMMA's transparency is outstanding compare with other plastics. Because it's stable mechanical and chemical characters , they are often used as an alternative to glass. Acrylic Parts are also very durable , with great UV resistance , which other plastic can't compete.

Extruded or Casted

Extruded or Casted

Extruded or Casted

Extruded PMMA thickness range from 2mm - 10mm ; and Casted PMMA from 3mm - 50mm. The differences are not only about thicknesses. Due to the production process, Casted PMMA have more solid mechanical structure, and more suitable for CNC precision machining.

Specifics of CNC

Extruded or Casted

Specifics of CNC

Due to PMMA's rigidness, it's very important to keep feed rate low from the beginning ,and gradually speed up. While processing and before machining, it's crucial to cool down the PMMA panels, and keep the temperature to a very minimum, it's very different from Metal

PMMA Engraving

PMMA Laser Process

Specifics of CNC

Engraving is one of most popular applications for PMMA, mostly for decoration and advertisement. To achieve ultra-precise and optimum optical goal, special tools are the must, and also the details after machining, like cleaning and polishing.

PMMA Laser Process

PMMA Laser Process

PMMA Laser Process

Laser cut is very common for cutting & processing PMMA to certain size or form without too much precision requirement like CNC. Without the precision , the cost is also much lower. Most of the PMMA projects are laser & CNC combined.

PMMA Molding

PMMA Laser Process

PMMA Laser Process

Molding is often applied to 1) mass production for certain pattern 2) bigger individual piece, which is impossible with CNC or Laser 3) Special design with certain surface requirement. Molding & Bending are very common processes for PMMA.

Metal CNC / Precision Machining

Production Area

Cookie Policy

This website uses cookies. By continuing to use this site, you accept our use of cookies.